5 STEPS of SUECS OPEX Methodology

i. Plant Maintenance: MRO, Preventive, Trouble Shooting

ii. Plant Integrity: NCR Non-Conformity Risk Assessment

iii. Manufacturing Programme: PQCDSM System Setup

iv. Continuous Improvement: KPI in practice

v. Build up Core Business Competitiveness

Notes: It is quite recommended that Modern Industrial Companies are concentrating and focusing on regular operating issues and ask 3rd Professional Parties to handle some temporary unplanned or unexpected issues...which will not only produce mostly efficiency but could also save much unknown risks.

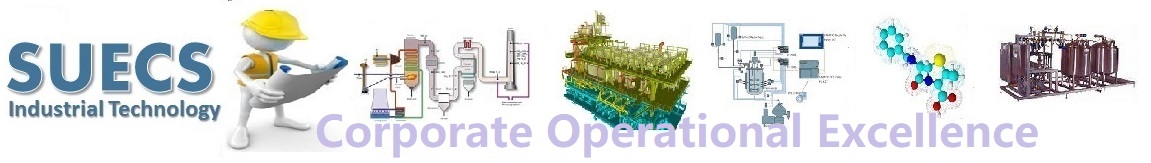

Stage I Plant Maintenance: Trouble-Shooting, Preventive Maintenance, MRO

1. Shutdown, Breakdown Diagnosis & Trouble Shooting Repair to Specific Equipment System;2. Preventive Maintenance, Overhaul Repair to Automatic Production Lines, Process Units;3. MRO Spare Parts Stocking Management;4. Planned Maintenance System Setup;5. Specialist, Well-trained Technician & labor Supports;6. Contractors or Supply Due Diligence Investigation, Remote Supervising & Startup Training;

References:

References:

Stage II Plant Integrity: NCR Non-Conformity Risk Control

1. NCR Non-Conformity or Compliance Legal Risk Internal Audit (Assessment);2. QEHS Incident/Accident Technical Investigation and Law Supporting;3. SCS@R NCR Audit, Assessment or Training to Suppliers, Contractors or Business Partners; References:

References:

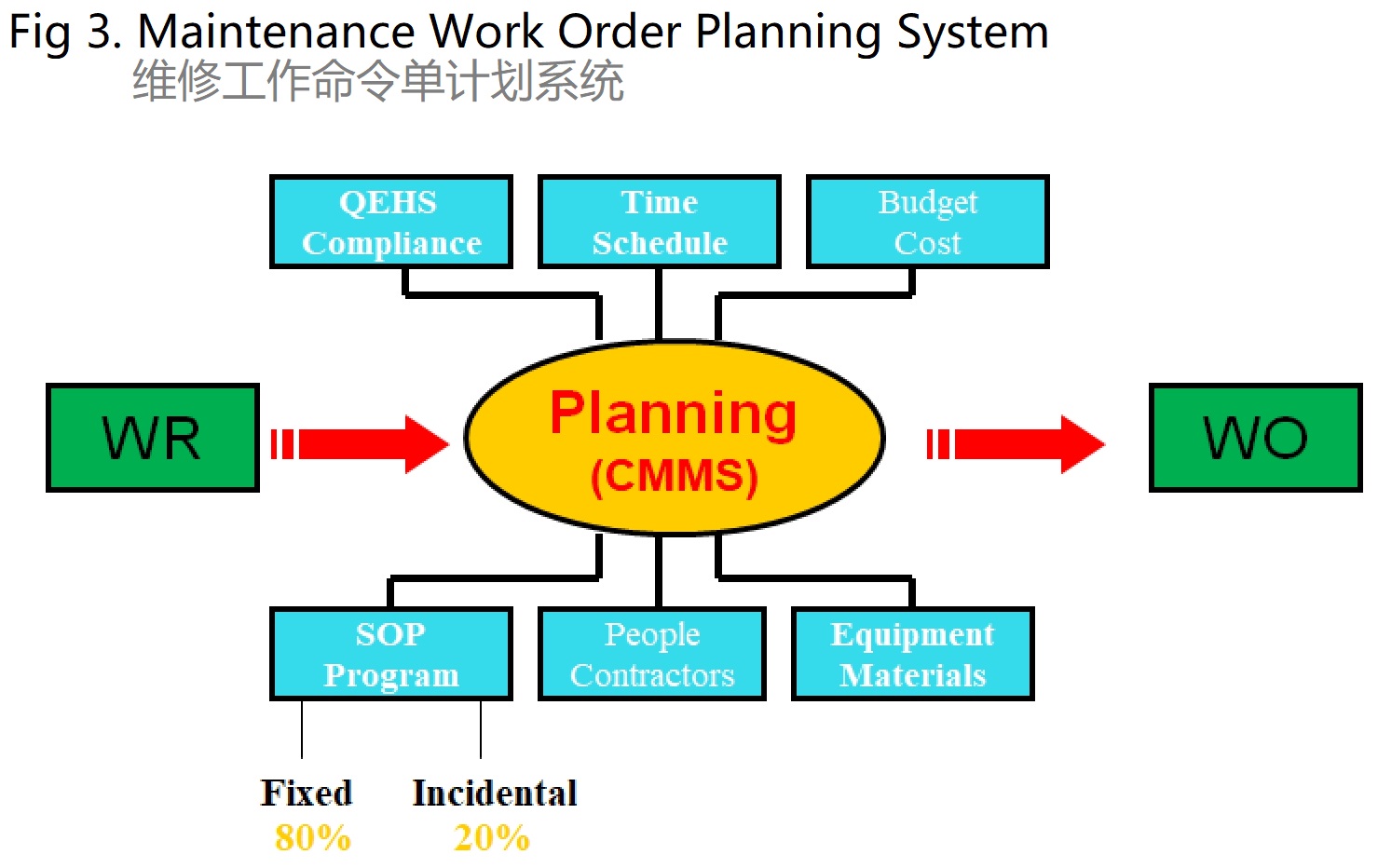

Stage III Manufacturing System Programme Buildup: PQCDSM

1. PQCDSM Plant KPI System (Targets Setting and Training);2. TPM: Planned and Preventive Maintenance System;3. QEHS & CSR Corporate Social Responsibilities;4. SCM Supply Chain Management System;5. CIM/CRM Customer Information Managing System;6. Skill Capabilities Module Developing System;

PQCDSM Performance Matrix

References:SUECS Corporate Culture Development Strategy Training Programme-2022

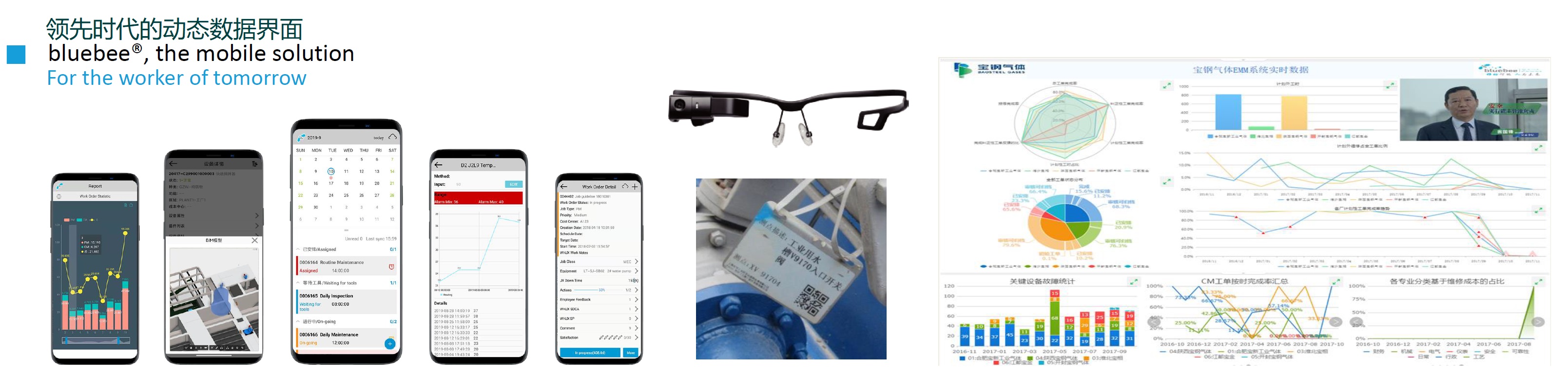

Stage IV Efficiency Improvement: KPI Methodology in Practice

1. PQCDSM KPI Performance 3rd Party Audit and Evaluation;2. Continuous Improvement: KPI Performance Targets Rationalizing and Benchmark Referring.3. People Teamworking & Motivating: RACI Methodology, Situational Leadership;4. Result-oriented Planning & Execution: POLC, PDCA; 5S & Lean; 5. Project Management: DMAIC5. Communication, Difference or Conflict Managing: SMART, RCA

References:

SUECS Industrial Technology-SCS Accreditation Programme

Stage V Build up Business COMPETITIVENESS

1. Products Specifications: Technology & SUECS Global SME Expertise Supports; 2. Brand Power & Corporate Image: SCS Accreditation & Verification3. Resources & Information Acquiring: SUECS Global SME4. Products Stewardship: SUECS Regional Centers, SCS@Y Accredited Agency-Customer Service Channels & Supports;5. Corporate Culture Strategics: SCS@R Accredited Membership Club, Culture communication on Products, Service, People, QEHS, Cost, Customer, NCR, Communication, Organization Structure & Tasks, and etc.