SCS Accredited Programme

-Market Developing, Customer Supports & Supply Management

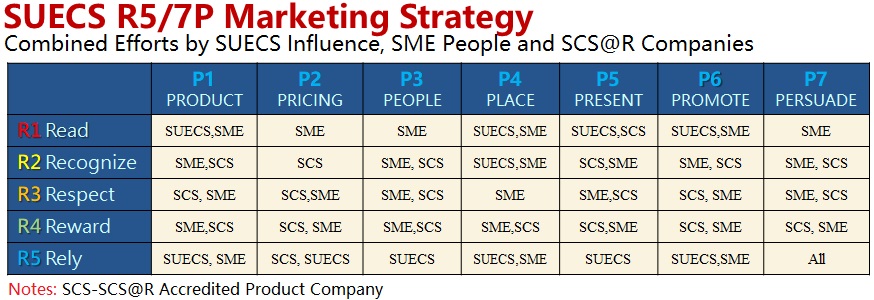

Global Marketing Strategic Collaboration

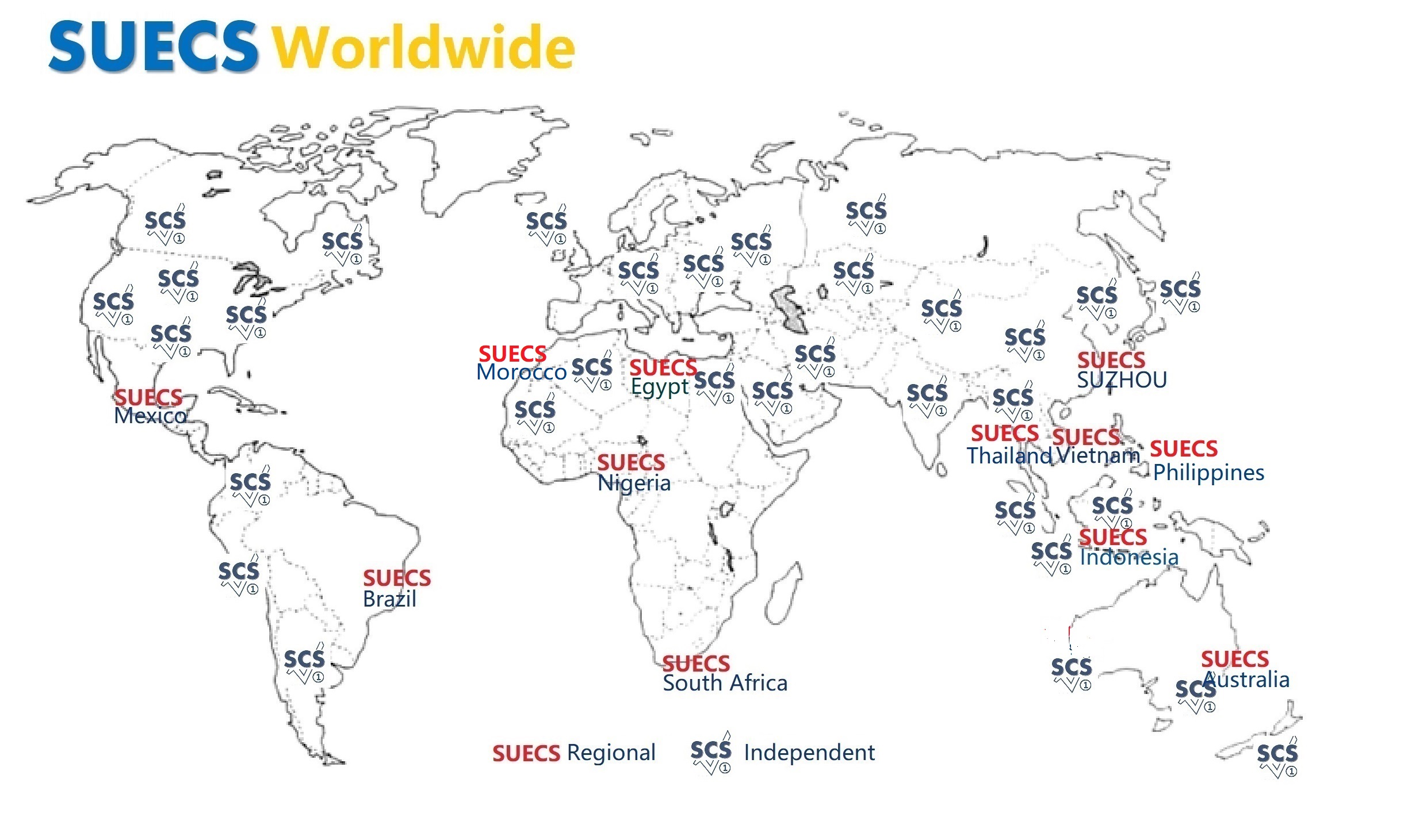

One good Marketing System normally should be included of at least following essential functions, such as:P1, Customer or Market-Oriented Product Studying System;P2, Valid Price Calculating and Adjusting Mechanism;P3, Sufficient and Highly Trained Marketing Professionals and Various Customer Supporting Technicals; P4, Tailored for fit Major Market or Key Account Solution Strategy;P5, What, Why, Who, Where, When, How, How much Action Plan;P6, Plan, Organise, Lead, Supervise & Control each of all activities;P7, Key account following up and contract order-raising methodology;There is few company who can find up wholly functions, not to mention worldwide customer supporting system. However, most companies can co-shared our SUECS Global Industrial Technology Supporting & Service Network, which can simply help and support your marketing and customer supporting challenges efficiently and economically.After 20 years of our consistent efforts, we have built up our SUECS Global Industrial Technology Supporting & Service System, which included of but not limited to: SUECS Worldwide SME Professional Network, SUECS Regional Centers & SCS Authorized Distribution Agents,SCS Accreditation Programme, SCS Accredited Products Categories;So that we can provide different Tailored for Fit Marketing Solution Service upon customer needs:1. Wholly Regional Marketing Development & Customer Supportive ;2. Key Account Market Project Solution;3. Specific Activities & Event Case Supporting;

One good Marketing System normally should be included of at least following essential functions, such as:P1, Customer or Market-Oriented Product Studying System;P2, Valid Price Calculating and Adjusting Mechanism;P3, Sufficient and Highly Trained Marketing Professionals and Various Customer Supporting Technicals; P4, Tailored for fit Major Market or Key Account Solution Strategy;P5, What, Why, Who, Where, When, How, How much Action Plan;P6, Plan, Organise, Lead, Supervise & Control each of all activities;P7, Key account following up and contract order-raising methodology;There is few company who can find up wholly functions, not to mention worldwide customer supporting system. However, most companies can co-shared our SUECS Global Industrial Technology Supporting & Service Network, which can simply help and support your marketing and customer supporting challenges efficiently and economically.After 20 years of our consistent efforts, we have built up our SUECS Global Industrial Technology Supporting & Service System, which included of but not limited to: SUECS Worldwide SME Professional Network, SUECS Regional Centers & SCS Authorized Distribution Agents,SCS Accreditation Programme, SCS Accredited Products Categories;So that we can provide different Tailored for Fit Marketing Solution Service upon customer needs:1. Wholly Regional Marketing Development & Customer Supportive ;2. Key Account Market Project Solution;3. Specific Activities & Event Case Supporting;

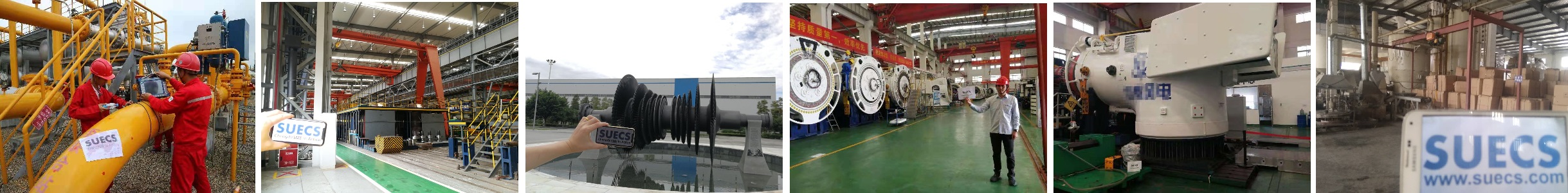

Remote Customer Localized SupportingNo customer supporting, no marketing!

As of modern hi-tech integrated and complicated, industry users always ask immediate customer service. However, most companies may not provide wholly supporting service, so that more and more of them are asking for market customer collaboration with our SCS 3rd Party Technology Service system to help their customer needs perfectly!Upon customer needs, we can provide more options of our localized supporting services, such as:1. Long-term engineer/specialist supporting at customer work site;2. Whole region area contracted;3. Specific Project On-site Service;4. Call for Urgent or Emergency;

As of modern hi-tech integrated and complicated, industry users always ask immediate customer service. However, most companies may not provide wholly supporting service, so that more and more of them are asking for market customer collaboration with our SCS 3rd Party Technology Service system to help their customer needs perfectly!Upon customer needs, we can provide more options of our localized supporting services, such as:1. Long-term engineer/specialist supporting at customer work site;2. Whole region area contracted;3. Specific Project On-site Service;4. Call for Urgent or Emergency;

Far-away Contract Fabricating, Supply & Delivery SupervisionContract just begin, Delivered is Result!

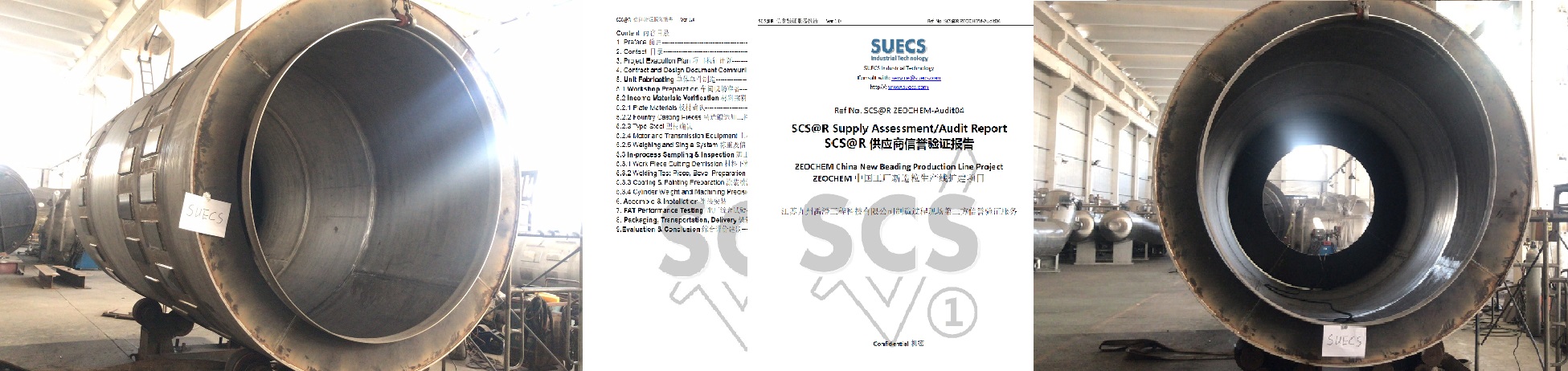

Supply NCR Non Compliance or Conformity Risk Control is one essential but very challenging work for business operations, especially on managing various of supply contractors at other locations. Similarly our SUECS is capable of providing remote supply fabricating QC Supervision and Delivery Tests, such as SAT, FAT works.We can accept whole or key works of Four Main Stage, such as:1. Early-stage Investigation, Verification, Pre-qualification;2. Contracting Risk Evaluating;3. Supporting Service on Execution such as Fabrication, Installation, Performance Testing;4. After Sales & Delivery Supporting Service;More about our Supply NCR Risk control, please see following Appendix II

Appendix II: SCS Accreditation Programme-Supply Process Management

SOURCING

SUECS are able to provide 3rd party Independent Supply Outsourcing & On-site Audit, even Special Background Investigation by our Global SCS@SME Professional System.

-Vendor Qualification Verifying;

- -SCS@R Accredited Categories for Selection;

Notes: Non-conformity findings

1) Wrong or Outdated License or Misuse Permits;

2) Unacceptable sub-contracting...

3) Company Difference: New Owner or Management, Key People loosing...

Reference

CONTRACTING

SUECS will enhance direct Supply and Customer communication since first moment, and can provide technology specification communicating supports and risk review by our highly experience SCS@SME Professional from each industries;

- -Specification Requirements Communicating & Verifying;

- -Proposal Review & Technology Validation;

- -Contract Gaps/Disputes Negotiation;

- -Contract Confirming: NCR Risk Assessment;

Notes: Non-Conformity findings

1) Confused Communication on Specification Requirements;

2) Unaffordable NCR, irrational Low-pricing Risk, Uncontrolled Sub-contracting or other Poison Contract Pitfalls...

3) No agreement method on future unexpected Changes...

4) Unclear Role Task & Responsibilities...

Reference

FBABRICATING PROCESS

We can carry out remote fabricating process supervision and quality inspection test by our worldwide SME system.

- -Work Execution & Deliverables Planning Review;

- -Remote Supply Site Condition Survey and Workshop Audit Verifying;

- -Incoming materials, parts, components quality control inspection;

- -Fabricating Process Supervision, Quality Check and Testing;

- -Remote Fabricating process check, inspection or SAT, FAT, SIT tests;

- -Remote Supply or Customer site Change Supporting and delivery coordinating;

Notes: Common Non-Conformity findings

1) off-spec steel materials, reused rubber plastics components, recovered electrical device or cables, repaired bearings, valves, gear parts, and etc;

2) Not enough control on surface cleaning, painting or lubricating, welding & bevelling, Assembling, Calibrating, Testing & Checking...

3) No working condition managing, especially with highly risk on fire, explosion, safety, health, environmental or people problems;

Reference

AFTER-DELIVERY SERVICE

After delivery, we can provide wholly or partly supports on follows by our experienced SME loaclly.

- -Installation & Performance Testing Supports;

- -Operating Preparation: Program & People Training, Safety Review, Work Permitting;

- -After-on New Requirements, Change & Improvement, Renewal or Modification, Spare Parts, and etc;

Notes: Non-Conformity findings

1) No local Supporting Service;

2) No Spare or Repair Parts Supply;

3) No Future Warranty Supports (Supplier too small to find at next year);

Consult us for more information by: business@suecs.com